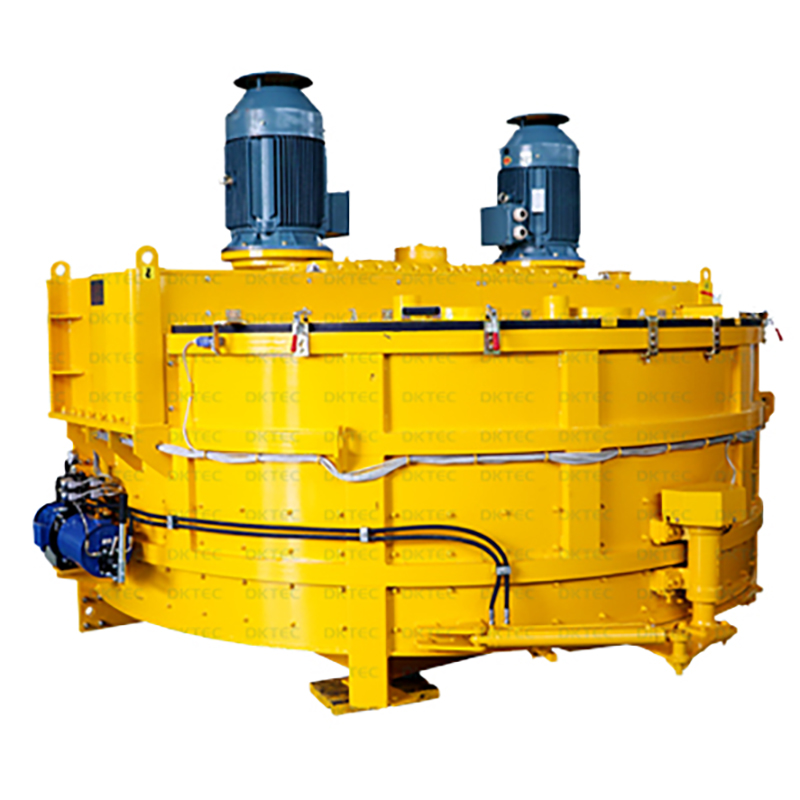

Semela se kopanyang konkreite sa HZS ke mochini o matla oa tlhahiso le lisebelisoa tse phahameng tse ka hlahisang mefuta e fapaneng ea konkreite. Ka ts'ebetso e phahameng ea tlhahiso, e sebelisoa haholo ho ahong e kholo le e mahareng, boenjineri ba tsela le lifeme tse hlokahalang bakeng sa ho hlahisa lihlahisoa tsa konkreite. Ke sesebelisoa se loketseng ho hlahisa konkreite ea khoebo. Sisteme ea eona ea ho kopanya e sebelisa mafahla a qobelloang a mafahla, a nang le ts'ebetso e ntle ea ho kopanya, nako e khuts'oane ea ts'ebeliso, bophelo bo bolelele ba ts'ebeletso ba likarolo tse apereng, le ts'ebetso e bonolo le tlhokomelo. E amohela theknoloji ea morao-rao ea taolo joalo ka sistimi ea boima ba elektroniki, taolo ea likhomphutha le ponts'o ea dijithale. Lisebelisoa tsa ho bekha ka elektroniki li na le lisebelisoa tsa lisebelisoa le mesebetsi ea matšeliso ka boiketsetso, ka nepahalo e phahameng ea litekanyo. Sisteme ea phepelo ea lehlabathe le lehlohlojane e amohela lebanta le leholo la herringbone bakeng sa ho fepa mme e na le litselana tsa maoto. Ke khetho e nepahetseng bakeng sa palo e kholo ea lisebelisoa tsa kaho ho hlahisa konkreite e ntlehali.

DKTEC e ka fihlela litlhoko tsa bareki habonolo ka limela tsa eona tse tsoakaneng tsa konkreite tse nang le bokhoni le litlhaloso tse fapaneng.

E na le mefuta e fapaneng ea lisebelisoa tse sa fetoheng tsa konkreite e kentsoeng, 'me matla a tlhahiso a mochini oa mochini o kopanyang a tloha ho 60m³ / h ho isa ho 180m³ / h. Hape re ka etsa tharollo ea litharollo ho latela litlhoko tsa bareki, lengolo tsoibila la rona: thekiso@dongkunchina.com

Ntle le moo, semeleng se ts'oanang sa konkreite se kopantsoeng le li-mixer tse peli, matla a tlhahiso a ka fihla ho li-cubic metres / hora tse 240 le li-cubic metres tse 360 / hora.

| Ntho | Yuniti | HZS25 | |

| Tlhahiso ea mohopolo | m³ / h | 25 | |

| Tlhahiso ea mochini o tsoakang | m³ | 0.5 | |

| Mofuta oa ho fepa | Ho phahamisa hopper | ||

| Moetso oa batcher | m³ | EA-800-PLD | |

| Batcher (molumo ka 'ngoe) | m³ | 3 | |

| Batcher (bins chelete) | pc | 4 | |

| Matla a mixer | KW | 18.5 | |

| Ho phahamisa matla | KW | 5.5 | |

| Bophahamo ba lero | m | 1.5 / 2.7 / 3.8 | |

|

Max boima

|

Kakaretso | kg | 1500 ± 2% |

| Lisebelisoa tsa phofo | kg | 300 ± 1% | |

| Pompo ea metsi | kg | ± 1% | |

| Pompo ea tlatsetso | kg | ± 1% | |

| Ntho | Yuniti | HZS35 | |

| Tlhahiso ea mohopolo | m³ / h | 35 | |

| Tlhahiso ea mochini o tsoakang | m³ | 0.5 | |

| Mofuta oa ho fepa | Ho phahamisa hopper | ||

| Moetso oa batcher | m³ | EA-800-PLD | |

| Batcher (molumo ka 'ngoe) | m³ | 3 | |

| Batcher (bins chelete) | pc | 4 | |

| Matla a mixer | KW | 30 | |

| Ho phahamisa matla | KW | 7.5 | |

| Bophahamo ba lero | m | 1.5 / 2.7 / 3.8 | |

|

Max boima

|

Kakaretso | kg | 2000 ± 2% |

| Lisebelisoa tsa phofo | kg | 500 ± 1% | |

| Pompo ea metsi | kg | ± 1% | |

| Pompo ea tlatsetso | kg | ± 1% | |

| Ntho | Yuniti | HZS60 | |

| Tlhahiso ea mohopolo |

m³ / h |

60 | |

| Tlhahiso ea mochini o tsoakang |

m³ |

1 | |

| Mofuta oa ho fepa |

|

Ho fepa lebanta | |

| Moetso oa batcher |

m³ |

EA-2400-QQ | |

| Batcher (molumo ka 'ngoe) |

m³ |

10 | |

| Batcher (bins chelete) |

pc |

4 | |

| Matla ohle |

KW |

92 | |

| matla a mixer |

KW |

2x22 | |

| E sekametse lebanta le tsamaisang lebanta |

KW |

11 | |

| Bophahamo ba lero |

m |

4.1 | |

| Boima bohle |

kg |

38000 | |

| Teba (L × W × H) |

m |

38x18x20.7 | |

| Max e bekha ho nepahala | Kakaretso |

kg |

1200 ± 2% |

| Samente |

kg |

800 ± 1% | |

| Lisebelisoa tsa phofo |

kg |

500 ± 1% | |

| Metsi |

kg |

250 ± 1% | |

| Lisebelisoa |

kg |

20 ± 1% | |

| Ntho | Yuniti | HZS90 | |

| Tlhahiso ea mohopolo |

m³ / h |

90 |

|

| Tlhahiso ea mochini o tsoakang |

m³ |

1.5 |

|

| Mofuta oa ho fepa |

|

|

|

| Moetso oa batcher |

m³ |

EA-2400-QQ |

|

| Batcher (molumo ka 'ngoe) |

m³ |

10 |

|

| Batcher (bins chelete) |

pc |

4 |

|

| Matla ohle |

KW |

130 |

|

| matla a mixer |

KW |

2 × 30 |

|

| E sekametse lebanta le tsamaisang lebanta |

KW |

22 |

|

| Bophahamo ba lero |

m |

4.1 |

|

| Boima bohle |

kg |

45000 |

|

| Teba (L × W × H) |

m |

39.5 × 18 × 20.7 |

|

| Max e bekha ho nepahala |

Kakaretso |

kg |

2400 ± 2% |

| Samente |

kg |

800 ± 1% |

|

| Lisebelisoa tsa phofo |

kg |

600 ± 1% |

|

| Metsi |

kg |

350 ± 1% |

|

| Lisebelisoa |

kg |

20 ± 1% |

|

| Ntho | Yuniti | HZS120 | |

| Tlhahiso ea mohopolo |

m³ / h |

120 |

|

| Tlhahiso ea mochini o tsoakang |

m³ |

2 |

|

| Mofuta oa ho fepa |

|

|

|

| Moetso oa batcher |

m³ |

EA-3000-PL |

|

| Batcher (molumo ka 'ngoe) |

m³ |

14 |

|

| Batcher (bins chelete) |

pc |

4 |

|

| Matla ohle |

KW |

180 |

|

| matla a mixer |

KW |

2x37 |

|

| E sekametse lebanta le tsamaisang lebanta |

KW |

30 |

|

| Bophahamo ba lero |

m |

4.1 |

|

| Boima bohle |

kg |

70000 |

|

| Teba (L × W × H) |

m |

38 × 26 × 22 |

|

| Max e bekha ho nepahala | Kakaretso |

kg |

3600 ± 2% |

| Samente |

kg |

1200 ± 1 |

|

| Lisebelisoa tsa phofo |

kg |

1200 ± 1 |

|

| Metsi |

kg |

600 ± 1% |

|

| Lisebelisoa |

kg |

50 ± 1% |

|

| Ntho | Yuniti | HZS180 | |

| Tlhahiso ea mohopolo |

m³ / h |

180 |

|

| Tlhahiso ea mochini o tsoakang |

m³ |

3 |

|

| Mofuta oa ho fepa |

|

|

|

| Moetso oa batcher |

m³ |

EA-483-QS |

|

| Batcher (molumo ka 'ngoe) |

m³ |

18 |

|

| Batcher (bins chelete) |

pc |

4 |

|

| Matla ohle |

KW |

275 |

|

| matla a mixer |

KW |

2x55 |

|

| E sekametse lebanta le tsamaisang lebanta |

KW |

45 |

|

| Bophahamo ba lero |

m |

4.1 |

|

| Boima bohle |

kg |

90000 |

|

| Teba (L × W × H) |

m |

45 × 20 × 22 |

|

| Max e bekha ho nepahala | Kakaretso |

kg |

4800 ± 2% |

| Samente |

kg |

1600 ± 1% |

|

| Lisebelisoa tsa phofo |

kg |

1600 ± 1% |

|

| Metsi |

kg |

800 ± 1% |

|

| Lisebelisoa |

kg |

100 ± 1% |

|

HZS letoto la lihlooho tse ho kopanya konkreiti e entsoe ka tsamaiso ea ho kopanya, Sisteme ea ho kopanya thepa, ho lekanya sistimi le sistimi ea taolo ea motlakase. E loketse libaka tsa kaho tse kholo le tse nyane, limela tsa sehlahisoa sa konkreite le limela tsa tlhahiso.

Ho kopanya sistimi

Mafahla theko samente konkreiti na le matla ho kopanya matla, junifomo tsoaka boleng le tlhahiso phahameng. E na le phello e ntle ea konkreite e nang le thatafala e ommeng, thatafala e ommeng, polasetiki le boholo bo fapaneng. Sistimi ea lubrication le sistimi e kholo ea shaft drive kaofela li kenngoe ka har'a sephutheloana sa mantlha, mme ts'ebetso ea ho bula mamati a haeteroliki e ka fetola ho buloa ha lemati le tsoang ha ho hlokahala. Shaft e kopanyang ea mochini o ka sehloohong oa ho kopanya e sebelisa theknoloji e khahlanong le mamarello ho thibela ka katleho ho bokellana ha samente ho shaft. The theko theko tiiso o inkela e ikhethang multiple tiisoa ha sebopeho ho ka tsela e atlehang ho thibela seretse dutla le ho etsa bonnete ba e tsoelang pele le ea nako e telele tshebetso ya tsamaiso eohle tsoaka. Sisteme ea ho hloekisa e amohela pompo ea metsi e nang le khatello e phahameng ea taolo le taolo ea matsoho, Likoti tsa metsi li fumaneha ka kotloloho kaholimo ho sekontiri se kopanyang, se ntlafatsang tšebetso ea ho kopanya, se eketsa moholi oa metsi, se fokotsa tšilafalo ea lerōle mme se tlosa bokello ba samente ka nepo. E loketse bakeng sa kaho e kholo, lik'hamphani tsa konkreite tsa khoebo, jj.

Sesebelisoa sa Batching se akaretsang

Khetha mochini o kopanyang; mochini oa phepelo o hlophisitsoe ka sebopeho sa "sehlahisoa" mme o fepuoa ke conveyor lebanta; e amohela mekhoa e 'meli ea lisebelisoa tse ikemetseng tse nang le boima ba lisebelisoa tse bokellanang; boima ba elektroniki, taolo ea PLC, pontšo ea dijithale; t e na le boima bo nepahetseng, ho nepahala ho batching ho phahameng, lebelo le potlakileng, ts'ebetso e matla ea taolo, ts'ebetso e bonolo, jj.

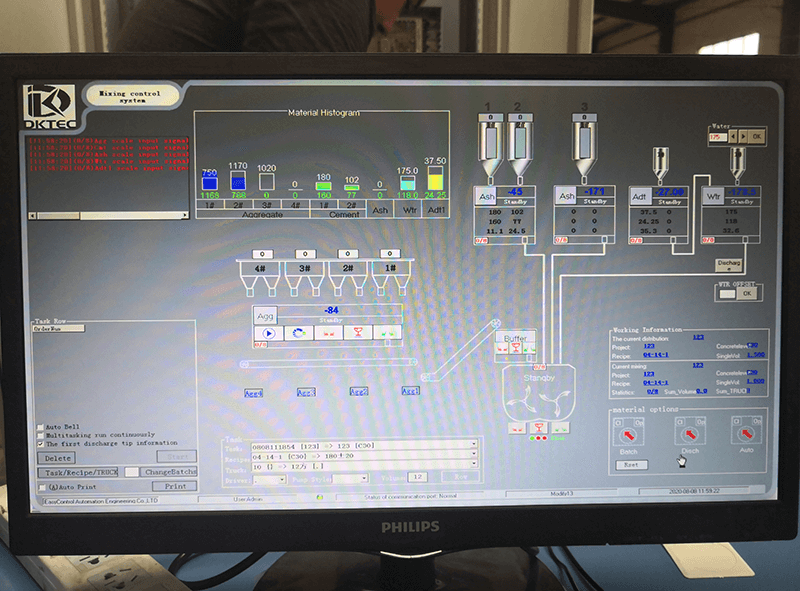

Tsamaiso ea taolo

Sebelisa likarolo tse tsoang kantle ho naha, ts'ebetso e tšepahalang; taolo ea hole, litokelo tsa mosebelisi li ka abeloa, ho fihlela lits'ebetso tsa mantlha tsa taolo ea projeke; taolo bohlale, jarolla ka ho iketsa taolo, pukwanana taolo e 'ngoe; ka polokelo ea karolelano, puseletso e ikemetseng ea lerotholi, tokiso e fetang tekanyo, khalemelo e tlase ea alamo; Lisebelisoa li na le mesebetsi e kang ho lekola ts'ebetso, ho boloka leru la data, khatiso, jj.

Tsamaiso ea ho bekha

Phofo, metsi le li-additives kaofela li lekantsoe ka sekala sa elektroniki; ho nepahala ha batching ho phahame mme tekanyo e nepahetse; samente, molora oa fofa, le hopper ea ho lekanya metsi e ts'ehetsoa foreiming ka li-sensor tse tharo, tse nang le sebopeho se tsitsitseng le ts'epahalo e phahameng; sehokedi metering Hopper e lekanngoa ka e le 'ngoe ts'ehetsana ntlha kutlo

Semela se seng le se seng sa ho kopanya se etselitsoe bareki!

Theko ea semela se seng le se seng se kopantsoeng e fapana ka lebaka la meralo e fapaneng!

Haeba u hloka ho tseba lintlha tse qaqileng tsa theko ea seteishene se senyenyane sa ho kopanya, u ka letsetsa mohala oa rona oa thekiso ka kotloloho: 0086-571-88128581

Ho ea ka phetolo eo u e hlokang, re tla fana ka khotheishene e nepahetseng ebe re u fa leseli leo u le hlokang ka nako e khuts'oane!

Tlhokomelo ea mochini oa konkreite

Etsa bonnete ba hore mochini le tikoloho e haufi li hloekile.

2.Clear bokella lintho tse bonahalang tse ka Hopper ka nako ea ho etsa hore kutlo khutlela zero ho tloaelehileng.

3.Hlahloba hore na oli e tlotsang ntlheng ka 'ngoe ea setlolo e lekane,' me setlolo se tsamaisong ea moea se lokela ho boloka oli e lekaneng.

Sheba hore na likoloi le lisebelisoa tsa motlakase li chesa haholo kapa ke lerata le sa tloaelehang, hore na sesupo se tloaelehile, le hore na sistimi ea lipontšo e sebetsa hantle.

5.Hlahloba le ho fetola silindara, belofo ea serurubele le valve ea solenoid khafetsa ho etsa hore ho bula le ho koala ho fihlelle litlhoko.

6.Hlahloba sistimi e ngoe le e ngoe khafetsa, 'me u sebetsane le eona ka nako haeba ho na le ho dutla ha lerole, ho dutla ha khase, ho dutla ha oli le ho dutla hoa motlakase.

7.The mixer le lero la mokoti le lokela ho hloekisoa lihora tse ling le tse ling tse 'ne ho thibela konkreite e setseng ho kopanya le ho sitisa ts'ebetso e tloaelehileng.

Phetoho e ngoe le e ngoe e lokela ho lokolla metsi a kahare a komporong ea moea, tanka ea polokelo ea moea le sefa, le ho felisa litlamorao tse etsahalang nakong ea ts'ebetso.

9.The belofo serurubele, mixer, belofo solenoid, moea filtara le sesebediswa moholi oli ba lula ba ho latela litaelo tse loketseng.